Silica, Synthetic Silica and Fumed Silica – Definition and Relationship

Silica, also known as silicon dioxide, is divided into two categories: natural silica and synthetic silica.

Natural silica

Natural silica is usually quartz powder or silica fumed/micro silica. Synthetic silica is an amorphous synthetic silicon oxide powder material.

Synthetic silica

Synthetic silica is white flocculent powder with physical properties of high-temperature resistance, non-combustibility, non-toxicity, odorlessness, and good electrical insulation.

Therefore, it is widely used in the fields of rubber, plastics, coatings, adhesives, sealants, insulation materials, and others.

Synthetic silica is classified according to manufacturing methods, mainly into fumed silica and precipitated silica.

fumed silica VS precipitated silica

What is fumed silica? – Definition & Properties

Fumed silica, also known as colloidal silicon dioxide, is made by high-temperature hydrolysis in a hydrogen-oxygen flame of silicon halides, mainly methyl silicochloroform (CH3SiCl3) or tetrachlorosilane (SiCl4). It is an amorphous nanoscale white powder with surface hydroxyl groups. Fumed silica appears as a white fluffy powder. It is a non-toxic, odorless, tasteless, and non-polluting inorganic oxide.

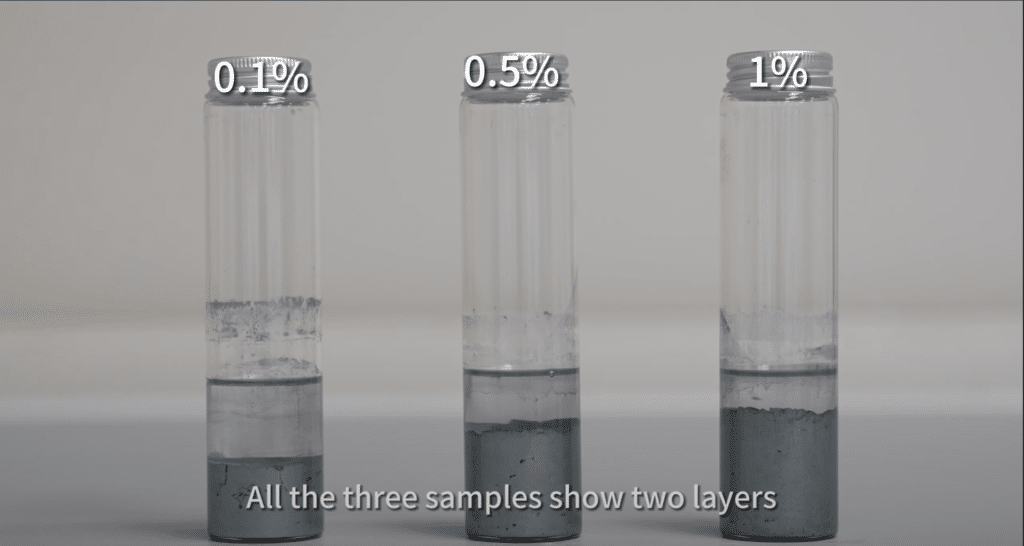

Fumed silica itself is hydrophilic, but its surface can be modified with hydrophobic groups to obtain hydrophobic fumed silica.

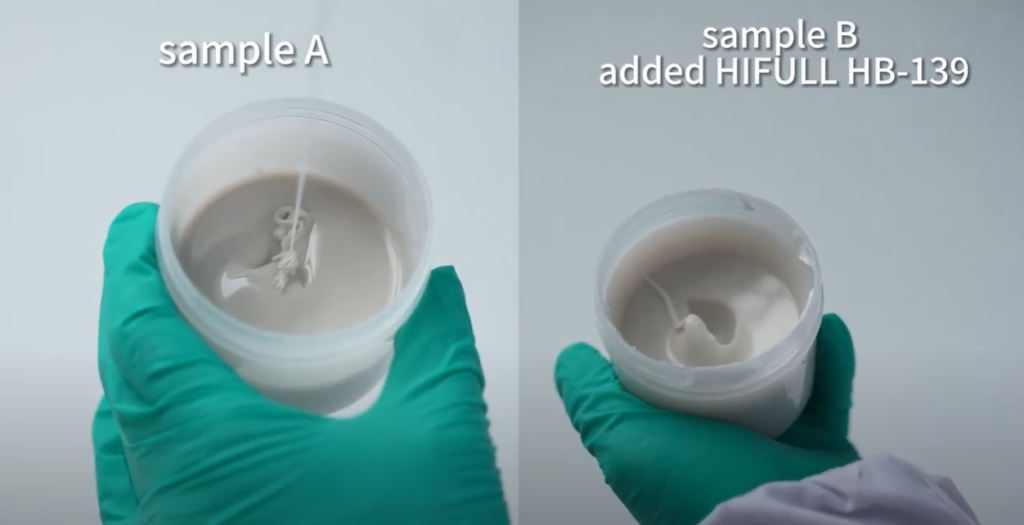

Fumed silica has an amorphous structure, small particle size, large specific surface area, high chemical purity and good dispersibility. It exhibits excellent performance in reinforcement, thickening, thixotropy, anti-settling, anti-sagging, moisture-adsorption, and thermal insulation.

Difference comparison table

The main differences between fumed silica and precipitated silica are in below aspects:

- Manufacturing methods & raw materials,

- Main Physico-chemical Data,

- Application Industries

- Cost & Price.

| Fumed Silica | Precipitated Silica | |

|---|---|---|

| Manufacturing methods & Raw materials | silicon halides, mainly methyl trichlorosilane and silicon tetrachloride, are used as raw materials. They undergo high-temperature combustion and hydrolysis with water in a gas-phase reaction | Typically, sodium silicate, sulfuric acid, or hydrochloric acid is used for neutralization and precipitation reactions in a liquid phase to prepare the product |

| Main Physical and Chemical Data | Purity ≥99.8%, moisture content typically less than 2%, free from crystalline water, is anhydrous silica dioxide, specific surface area ranges from 100-400 ㎡/g, low drying loss, and surface contains highly active silicon hydroxyl groups. The primary particle size of silica dioxide is between 7-40nm | Purity≥98%, moisture content 4-8%, ignition loss≤7%, specific surface area typically ranges from 100-200㎡/g, higher drying loss compared to fumed silica products |

| Application Industries | Fumed silica is widely used in various industries such as the silicone industry, mainly silicone rubber, printing inks, coatings, synthetic resins, adhesives, chemical mechanical polishing, composite materials, thermal insulation materials, colloidal batteries, pharmaceuticals, personal care products, and food. | Precipitated is used in industries such as rubber, tires, footwear manufacturing, toothpaste, animal feed, paints and coatings, and battery separators. |

| Cost and Price | Purity ≥99.8%, moisture content typically less than 2%, free from crystalline water, is anhydrous silica dioxide, specific surface area ranges from 100-400 ㎡/g, low drying loss, and the surface contains highly active silicon hydroxyl groups. The primary particle size of silica dioxide is between 7-40nm | low raw material cost and price compared to fumed silica |

Further Reading:

Difference Between Fumed Silica & Precipitated Silica & Silica Fume

Related Products

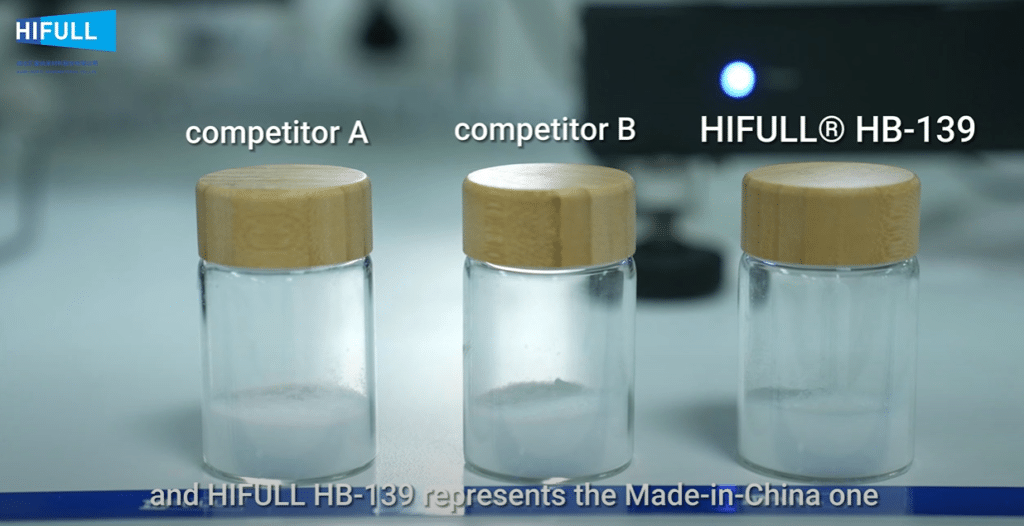

Hubei Huifu Nanomaterial Co., Ltd. manufactures more than 10 grades of fumed silica, both hydrophilic and hydrophobic. We get ISO, REACH, and participate in setting ISO18473-3-2018, ISO18473-1-2015, and ISO23157. We are strong in R&D product quality and factory capacity. Feel free to contact us by email: tww@hifull.com

ABOUT HIFULL

Our main products are fumed silica SiO2, fumed titanium dioxide TiO2, and fumed alumina Al2O3. We get 20+ years of expertise and 20,000 tons of annual capacity. We supply total of 23 grades of hydrophilic & hydrophobic fumed silica. We get registration of REACH and pre-registration of K-REACH & KKDIK. We are the leading setting body of ISO18473-1:2015, ISO18473-3:2018, and ISO 23157:2021. Learn More About Hifull

Frequently Asked Question

Still have questions?

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.