How to Improve Thixotropic Behavior of PVC Glue for Vertical Applications

Applying PVC glue or adhesives on vertical materials can sometimes be a challenge due to gravity, PVC adhesives tend to flow out. This not only stains the base material but also leads to waste of the glue, Improving its thixotropic properties can effectively solve the problem:

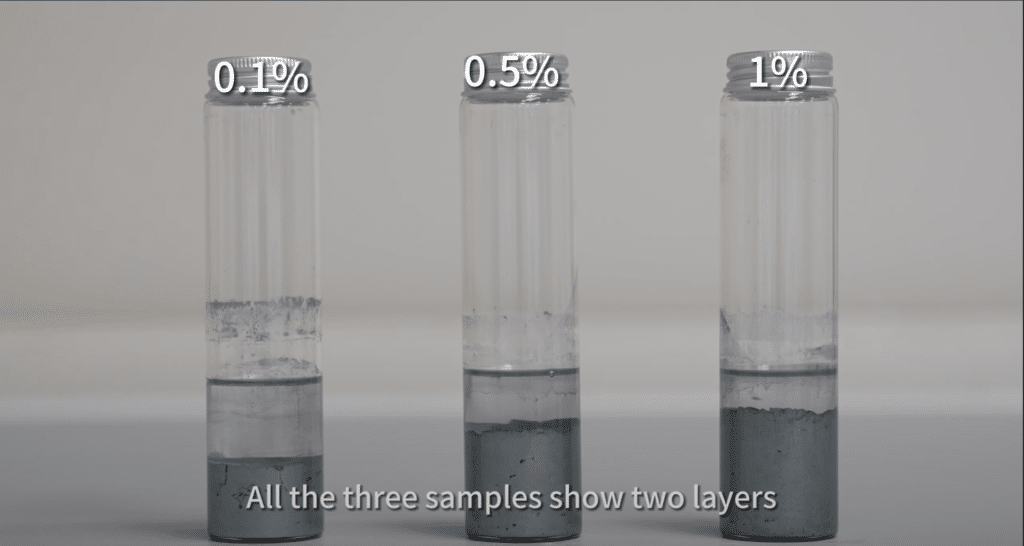

- Take three equal portions of PVC glue

- one portion is left untreated

- while adding 0.5% and 1% of HIFULL® HL-200 respectively into the other two portions

- Disperse them for 20 minutes with a high-speed disperser at 1000rpm

- All PVC glues are thoroughly dispersed

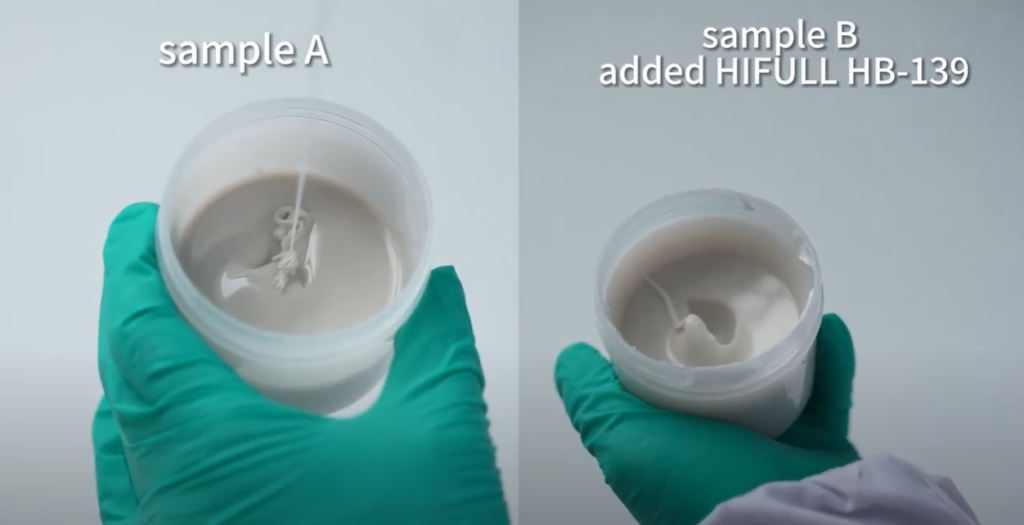

To simulate the construction situation and observe the flow ability of the glue, we pour the three PVC glue samples out

when coming to a standstill, the PVC glue without fumed silica forms the largest disc shape. The one added 0.5% of HIFULL® HL-200 is smaller and the 1% one is the smallest.

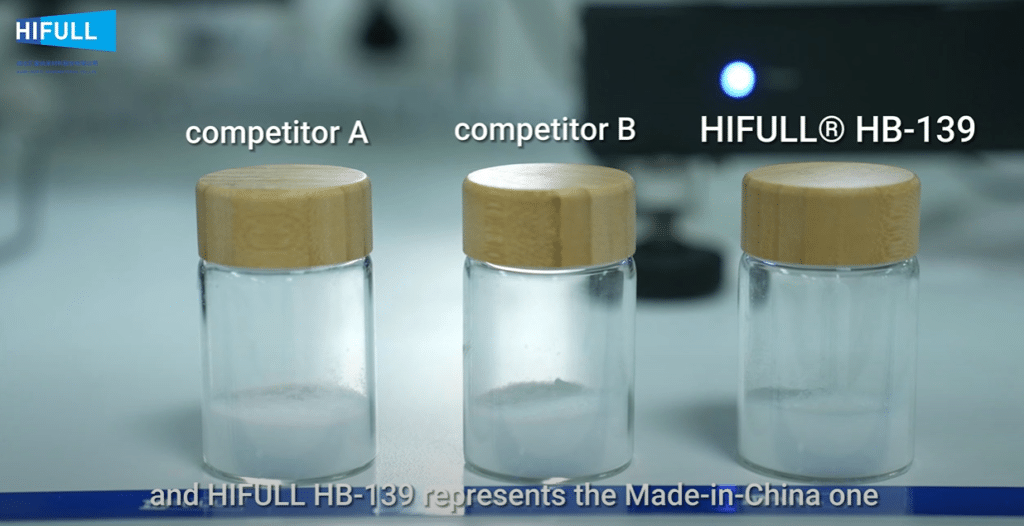

HIFULL® HL-200 (BET=200㎡/g)

Desired thixotropic properties of PVC glue can be achieved by controlling the added percentage of fumed silica. To accurately assess their thixotropic value, we use a Brookfield viscometer to measure the three samples.

Result shows that the PVC glue added 1% HIFULL® fumed silica has the largest thixotropic value. As the required thixotropic properties of PVC glue are related to practical usage, please check with our technical person to add a percentage of fumed silica based on your specific application needs.

Related Products

Hubei Huifu Nanomaterial Co., Ltd manufactures 7 grades of hydrophilic fumed silica and 10 grades of hydrophobic fumed silica for your choice. We are strong in R&D product quality and factory capacity. Feel free to contact us by email: tww@hifull.com

ABOUT HIFULL

Our main products are fumed silica SiO2, fumed titanium dioxide TiO2, and fumed alumina Al2O3. We get 20+ years of expertise and 20,000 tons of annual capacity. We supply total of 23 grades of hydrophilic & hydrophobic fumed silica. We get registration of REACH and pre-registration of K-REACH & KKDIK. We are the leading setting body of ISO18473-1:2015, ISO18473-3:2018, and ISO 23157:2021. Learn More About Hifull

Frequently Asked Question

Still have questions?

If you cannot find an answer to your question in our FAQ, you can always contact us and we will be with you shortly.