Difference Between Fumed Silica & Precipitated Silica & Silica Fume

Fumed silica and precipitated silica are both synthetic amorphous silica, but they are different in many properties. In this video, we will explain their difference in 3 main aspects.

1, the manufacturing process

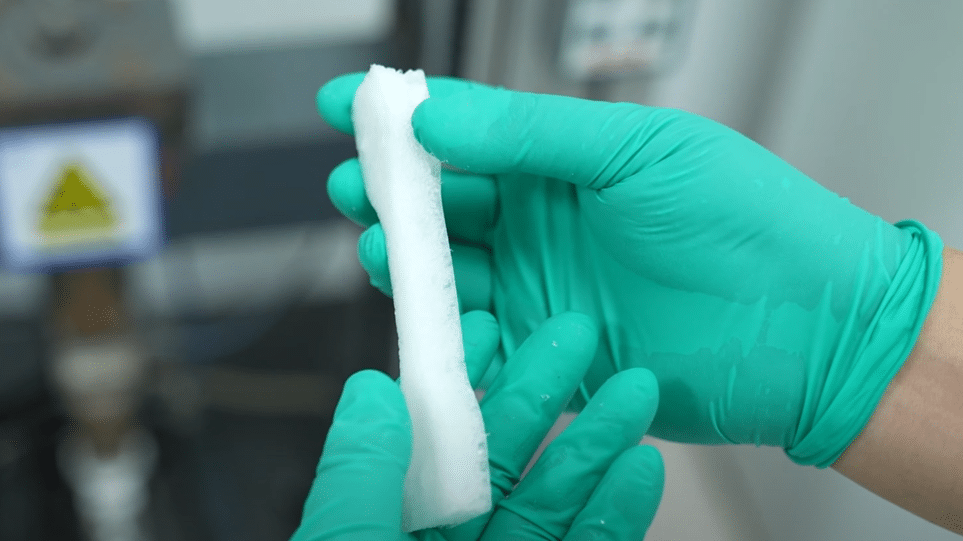

Fumed silica is manufactured in the pyrogenic process. It’s synthesized from the hydrolysis of high purity silane in a flame of oxygen and hydrogen at a very high temperature.(learn more: What are the materials and processes used to manufacture fumed silica?)

SiCl4 + 2H2O → SiO2 + 4HCl

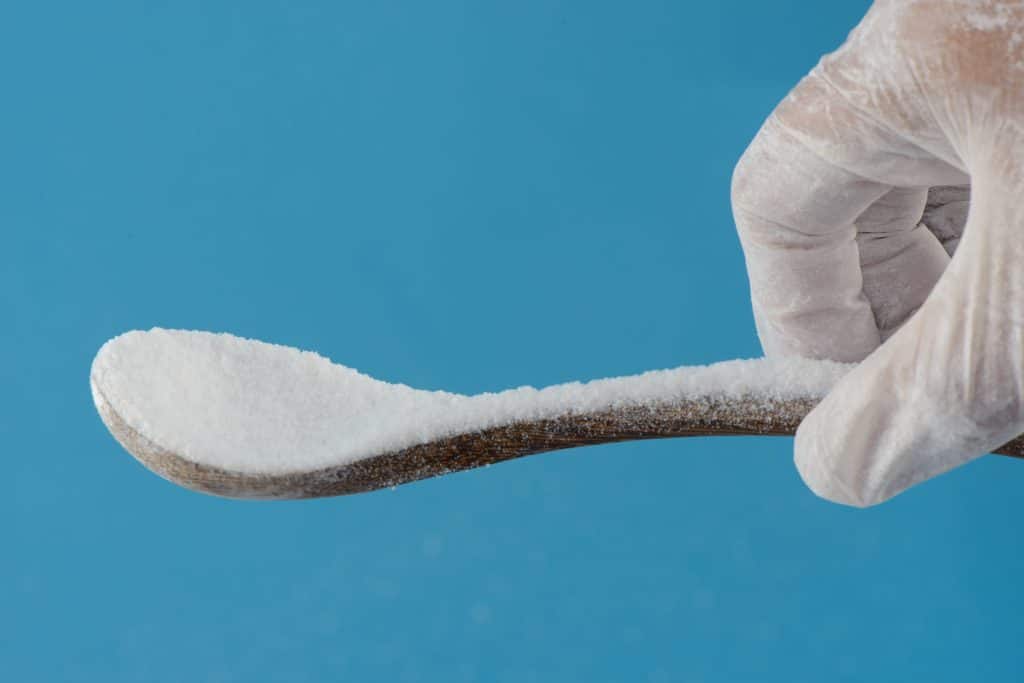

While Precipitated silica is manufactured in a wet-chemical process. It is produced by the controlled neutralization of dilute sodium silicate (water glass).

Na2SiO3 + 2HCL → SiO2 + 2NaCl + H2O

2, chemical properties

Fumed silica has a high specific surface area & small particle size. The aggregates size of fumed silica is 150-300 nanometers, it has 99.8% of silica content, and low moisture content. While precipitated silica is 1-100 micron meters, around 90% silica content and high moisture content.

Fumed silica, that is amorphous silica produced in the flame method from silica, is NOT the same as silica fume. The average particle size of fumed silica is 7-40 nm. while the average particle size of silica fume is 0.1-0.15 μm.

3, product functions

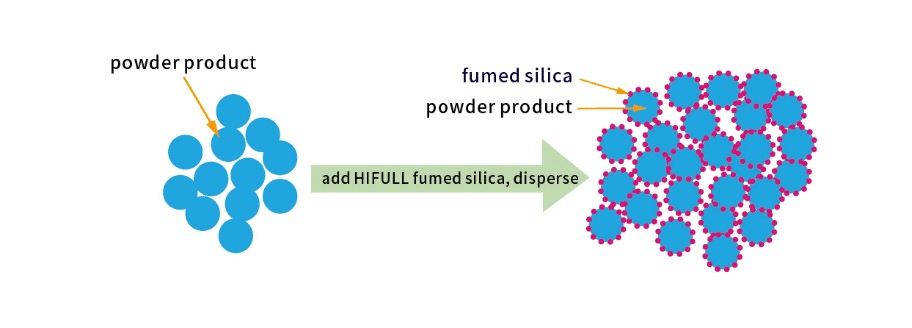

Fumed silica has better performance in thickening, thixotropy, sag resistance, reinforcement and caking resistance. While precipitated silica is mainly used as a reinforcing agent for rubbers or friction agent in toothpaste.

| Fumed Silica | VS | Precipitated Silica |

| 150-300 Nano meter | AGGREGATES SIZE | 1-100 Micron meter |

| >99.8% | SILICA CONTENT | >90% |

| 90-400㎡/g | SPECIFIC SURFACE AREA | 50-600 ㎡/g |

| Low | MOISTURE CONTENT | High |

| Fumed silica is synthesized from the hydrolysis of high purity silane in a flame of oxygen and hydrogen at a very high temperature. | MANUFACTURING PROCESS | Precipitated silica is produced by the Controlled neutralization of dilute sodium silicate (water glass) by either concentrated sulfuric, hydrochloric or carbonic acids. |

| High specific surface area, small particle size | FEATURE | Low specific surface area, large particle size |

| Has better performance in thickening, thixotropy, sag resistance, reinforcement, caking resistance; mainly used for industries that need high transparency, high purity & small surface area. | FUNCTIONS | Precipitated silica is mainly used as natural rubber and synthetic rubber reinforcing agent, friction agent in toothpaste. |

| Competitive price with international brand | PRICE | Lower than fumed silica |

HIFULL manufactures more than 10 grades of hydrophilic and hydrophobic fumed silica for your special choice. For product TDS, MSDS or sample-testing, price quotation, please check Datasheet or leave message to us.