Fumed Silica Used as Reinforcing Agent

What is reinforcing agent?

Reinforcing agent, as a kind of filler to enhance the strength of materials, its main function is to optimize the material mechanical properties, such as strength, hardness, tear resistance, tensile strength, toughness, heat resistance, weather resistance, etc.

There are many kinds of reinforcing agents, which can be used in rubber, adhesives, plastics and other traditional materials, but also in carbon fiber composites, concrete and other new materials.

Why need to be reinforced?

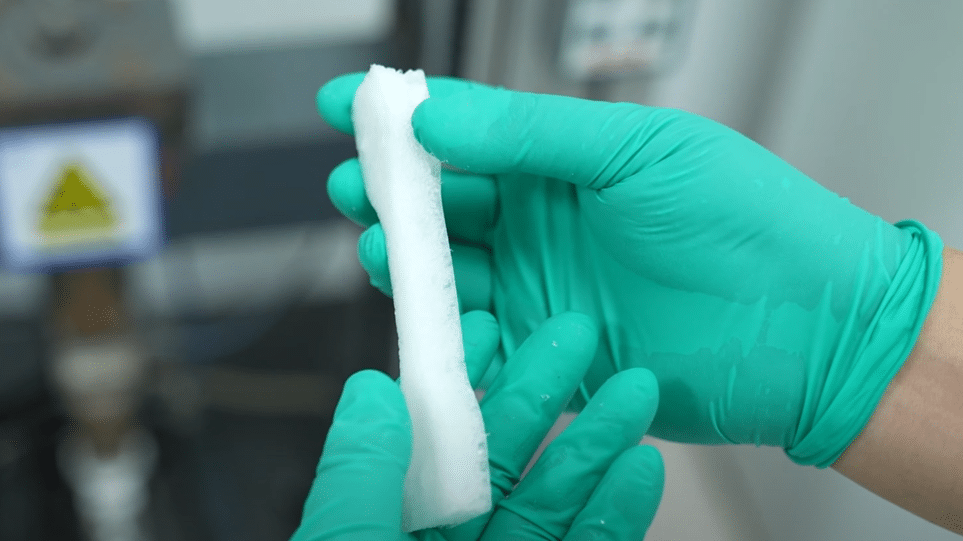

Many materials can hardly meet the needs of practical use. For example, silicone rubber, as a high-performance material, has properties of thermal resistance, heat insulation, electricity insulation, moisture-proof, anti-corrosion, anti-corrosion and physiological inertia, and is widely used in aviation, aerospace, national defense, machinery manufacturing, building decoration, biomedicine and other fields. However, as the molecular chain of silicone rubber is very flexible, the interaction between chains is weak, it needs to be reinforced to reach the practical application level.

Silicone Rubber

The most commonly use reinforcing agent are white carbon black, includes fumed silica and precipitated silica, carbon black, precipitated calcium carbonate, magnesium carbonate, zinc oxide, and so on.

Fumed silica, or pyrogenic silica, CAS#112945-52-5, is made by high-temperature hydrolysis in a hydrogen-oxygen flame of silicon halides, mainly methyl silicochloroform (CH3SiCl3) or tetrachlorosilane (SiCl4). It is an amorphous nanoscale white powder with surface hydroxyl groups.

Its primary particle size is between 7-40 nm, the specific surface area is generally in the range of 100 m2/g ~ 400 m2/g. It is with high purity, SiO2 content is not less than 99.8%. It has the functions of reinforcement, thickening, thixotropy, flow aid, suspension aid, anti-sedimentation and so on.

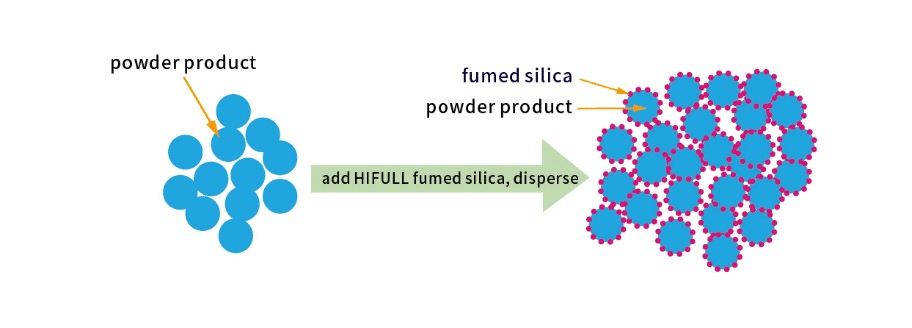

How fumed silica helps in reinforcement

Fumed silica is an ideal reinforcing agent. For example, in silicone rubber, the surface silicon hydroxyl (Si-oh) of fumed silica can form physical or chemical combination with silicone rubber macromolecules, thus resulting in a silicone rubber molecular adsorption layer, forming a three-dimensional network structure of silica particles and silicone rubber molecules. And this network effectively limits the deformation of silicone rubber molecular chains, to achieve reinforcement.

Application of fumed silica as reinforced agent

Hubei Huifu Nanomaterial Co., Ltd. produces hydrophilic and hydrophobic fumed silica with different grades, which is widely used as reinforcing agent in silicone rubber, adhesives, sealants and resin materials industries.

Grade suggestions for different application

Silicone rubber

Related Project: Fumed Silica For HTV Rubber | China

Adhesive

Related Project: Hydrophobic Fumed Silica For Silicone Adhesive | China Project

Elastomer

- HL-200, HB-620 are recommended for polyurethane systems;

- HL-200, HB-152 are recommended for organosilicon system.