The Application of Fumed Silica in Powder Anti-caking

The Particle Size of Fumed Silica in Anti-Caking

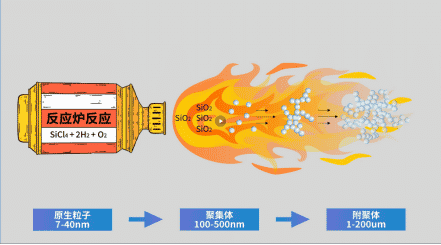

The primary particle size of fumed silica is 7-40 nm, and when it is dispersed in end product, its particle size is 80-2000 nm. The specific particle size desire is closely related to the downstream dispersion process.

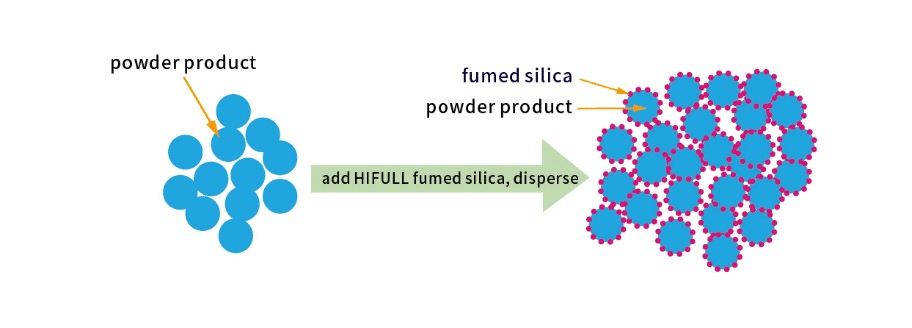

The excellent particle size of fumed silica enables it to be dispersed and wrap the target powder, thus forming a layer to isolate the target powder, increasing the free flow performance of the powder and preventing the powder from caking.

Fumed Silica Size & Property

How to choose the right device to disperse fumed silica and target powder

What’s the relation between the dispersing device, target powder and fumed silica? How to choose the right device to disperse fumed silica and target powder?

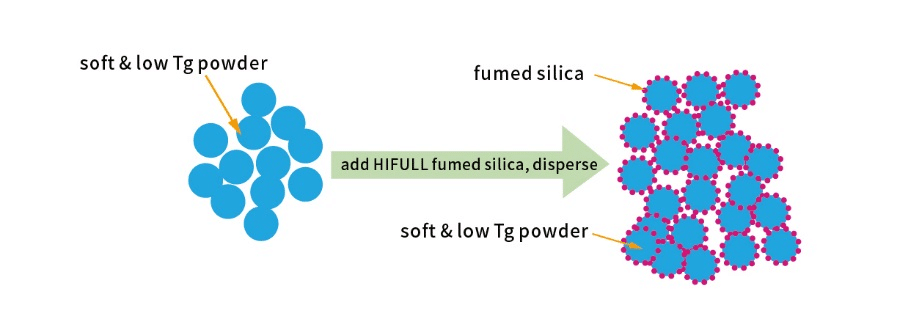

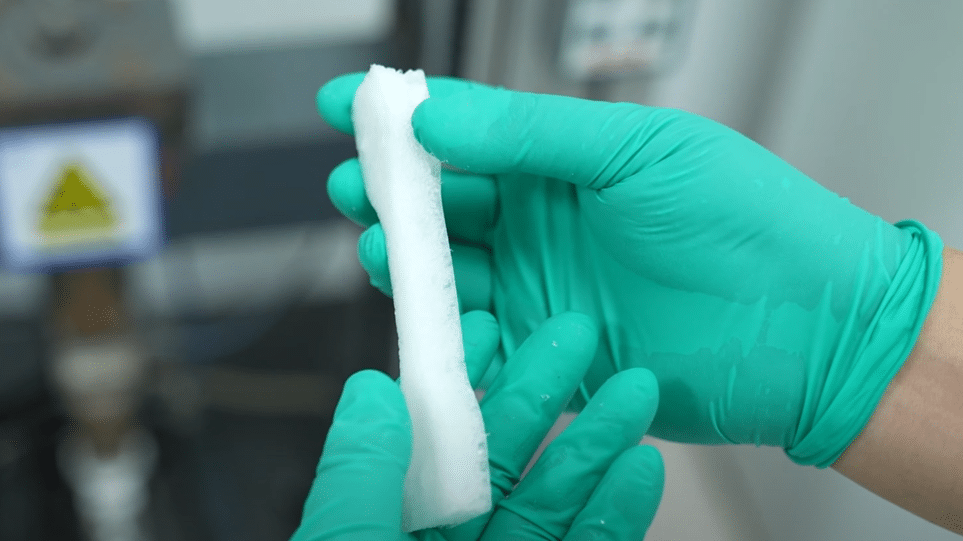

Based on laboratory data, the greater the dispersion force, the better the dispersion uniformity and the smaller particle size of fumed silica, resulting in excellent flowing properties of the target powder. However, in soft and low TG/glass transition temperature powders, the greater the dispersion force, the easier it is for fumed silica to stick with the target powder. In this case, the flowing ability of powders decreases, as the below picture shows:

So flow aid or anti-caking agent for powders should be chosen based on the properties of the target powder, and the dispersion process has great impact on the performance.

Learn More About Fumed Silica Used as Anti-caking Agent