Hydrophobic Fumed Silica | Applications and Product Polarity

Hydrophobic fumed silica is prepared by modifying hydrophilic fumed silica by treating agents of HMDS(Hexamethyldisilazane), PDMS(Polydimethylsiloxane), DDS(Dimethyldichlorosilane), or special silane. (Why fumed silica need to be treated to be hydrophobic?)

- Hydrophobic Nature: Repels water molecules; doesn’t mix or disperse in water, making it essential for water-resistant applications.

- Rheology Control: Modulates flow properties of liquids; ensures ease of pouring, spreading, or application.

- Thickening Agent: Increases viscosity in polar liquids, ensuring desired consistency and texture in formulations.

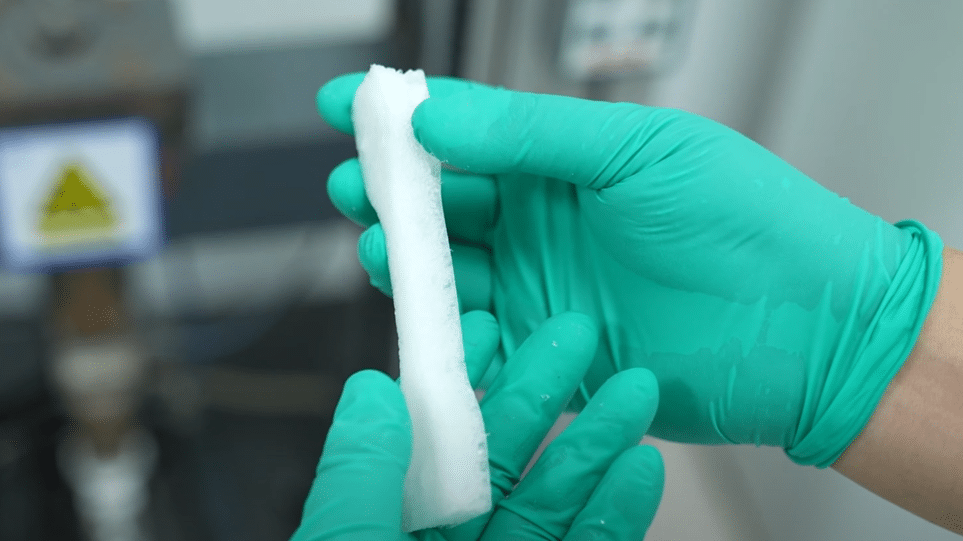

- Reinforcing Agent: Adds strength and durability to elastomers, enhancing their performance and lifespan.

- Improves Hydrophobicity: Enhances water resistance, making products less prone to water damage or degradation.

- Corrosion Resistance: Offers a protective layer, preventing materials from corroding, especially when exposed to harsh environments.

- Enhanced Dielectric Performance: Boosts electrical insulating properties, beneficial in electronic applications.

- Improved Scratch Resistance: Provides a protective barrier, reducing the risk of surface scratches and enhancing product durability.

Hydrophobic fumed silica has low polarity, makes it suitable for products of medium or high polarity systems, medium polarity systems products including polyurethane, polyols, polyimide, etc, and high polarity system products such as epoxy resin, vinyl resin, amine substances, cyanoacrylate, isocyanate (e.g., MDI, TDI), and polar solvents (e.g., alcohols, ketones, acetates). Hydrophobic fumed silica is also suitable for some low polarity system products such as MS Polymer, STP-E, polyacrylic acid acetate, polysulfide, etc.

As the differences in the polarity of hydrophobic fumed silica, variations in compatibility with different chemical system products exist, Please check the below table based on their specific product polarities for usage:

| Polarity Level | Materials/Products | Recommended Fumed Silica |

|---|---|---|

| Non-polarity Product | Methyl Organosilicon PVC (Polyvinyl Chloride) Aromatic/Aliphatic Hydrocarbons (e.g., Butyl, Styrene) Non-polar Solvents (e.g., THF – Tetrahydrofuran) | HIFULL HL-380 HIFULL HL-300 HIFULL HL-200 HIFULL HL-150 |

| Low-polarity Product | MS Polymer STP-E Polyacrylic Acid Acetate Polysulfides | HIFULL HB-152 HIFULL HB-151 |

| Medium-polarity Product | Polyurethane Polyols Polyamides | HIFULL HB-139 |

| High-polarity Product | Epoxy Resins Vinyl Resins Amine Compounds Cyanoacrylate Isocyanates (e.g., MDI, TDI) Polar Solvents (e.g., Alcohols, Ketones, Acetic Solutions) | HIFULL HB-139 |

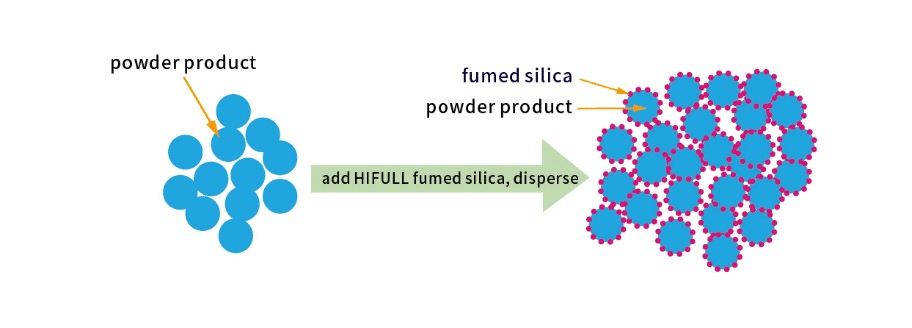

Hydrophobic fumed silica possesses low hygroscopicity, excellent dispersibility, and the ability to regulate rheology in polar systems. Some HIFULL hydrophobic fumed silica with post-treatment and structure modification can further assist customers in developing new products and improving product performance.