Fumed Silica Performance | Thickening &Thixotropic Functions

what are Thickening and Thixotropic functions?

Thickening and thixotropic functions refer to the properties exhibited by certain substances or additives that can increase the viscosity of a liquid and alter its flow behavior under applied stress or shear forces.

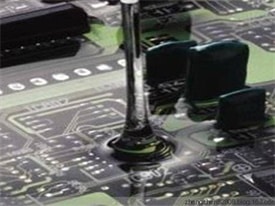

Thickening agents enhance the stability, texture, and consistency of liquid products, preventing them from becoming too thin or runny. Thixotropic behavior allows for easy application or dispensing of the liquid, as it can flow or spread more readily under applied shear forces while maintaining the desired viscosity and preventing undesirable dripping or sagging.

How does fumed silica exhibit its thickening and thixotropic?

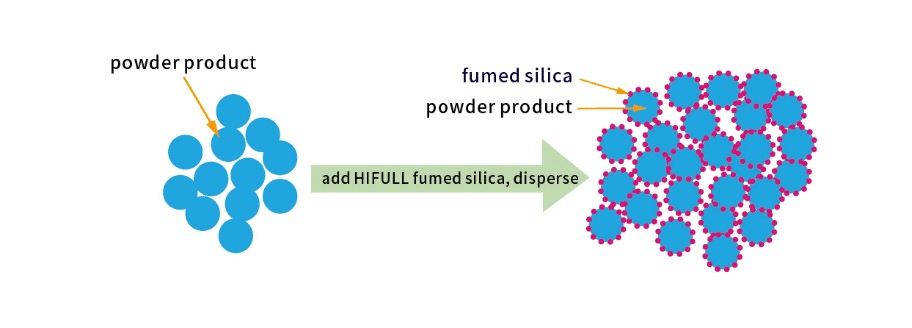

The surface of fumed silica is rich in silanol groups (Si-OH). These silanol groups enable the formation of hydrogen bonding among silica particles, creating a network structure of fumed silica. Additionally, the silanol groups can also form hydrogen bonds with the matrix (such as polar liquids or polymeric materials). As a result, a “interpenetrating network” is formed between fumed silica and the matrix, leading to effective thickening behavior.

The hydrogen bonds and physical adsorption forces that form the network are relatively weak, making the network easily disrupted under shear forces. This rapid disruption of the network causes a decrease in viscosity. However, once the shear forces are removed, the network quickly re-forms, leading to a rapid increase in viscosity. This behavior is characteristic of thixotropic properties.

Recommended Application and Product

Coatings: In the coatings and paint industry, fumed silica serves as an excellent rheology modifier. It increases the viscosity of the system while facilitating easy application and preventing sagging.

Recommended HIFULL Product:

Adhesives: With its good thickening and thixotropic behavior, fumed silica enables smooth application of adhesives, especially on vertical substrates, ensuring uniformity, controllable thickness, and resistance to flow and slump.

Recommended HIFULL Product:

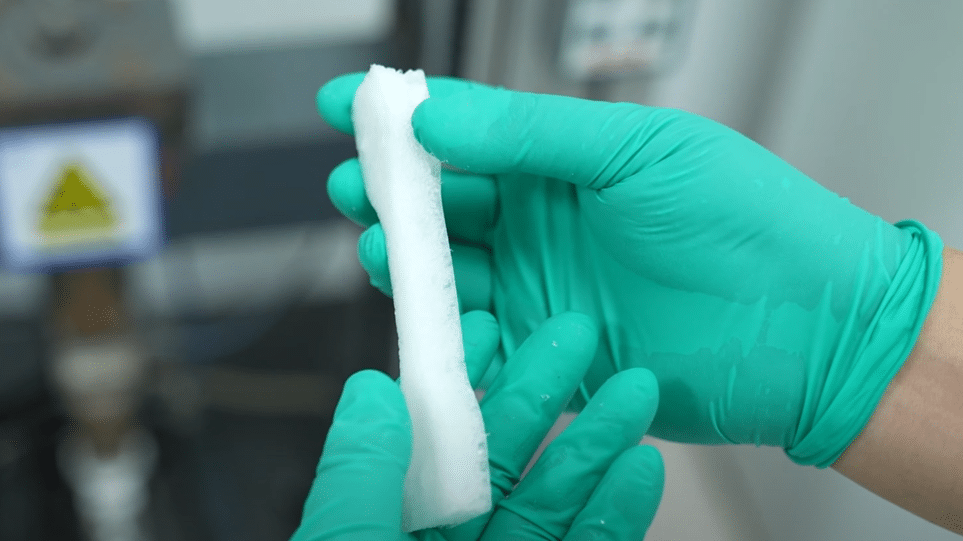

Resins: Without compromising transparency, fumed silica enhances the viscosity and thixotropic properties of resins, imparting excellent tensile strength, flexural performance, water resistance, heat resistance, and prolonged service life.

Recommended HIFULL Product:

Pesticides: It increases the viscosity of the system, reducing settling, agglomeration, and layering of active ingredients caused by density differences between the active ingredient and the dispersing medium under the influence of gravity.

Recommended HIFULL Product:

Concrete: Fumed silica enhances the consistency and stability of concrete admixtures, preventing the settling and agglomeration of major components such as sodium aluminate and sodium carbonate, thereby ensuring the overall consolidation and hardening of concrete.

Recommended HIFULL Product:

Further Reading: Why is it necessary to increase the viscosity and thixotropic Functions in a liquid system?

In a liquid system, the addition of viscosity and thixotropic behavior serves several important purposes. When a liquid product is too thin or runny, it becomes difficult to handle and use effectively. By increasing its viscosity, the product’s consistency is enhanced, making it easier to apply or dispense as desired. This is particularly crucial for products that require controlled flow, precise dosing, or adherence to vertical surfaces.

Moreover, the inclusion of thixotropic behavior in the liquid formulation is essential for maintaining stability and preventing issues during storage. Without proper thickening and thixotropy, heavier solid particles or fillers in the liquid may settle over time, leading to sedimentation or phase separation. By increasing the viscosity and imparting thixotropic properties, the liquid system becomes more resistant to settling, ensuring uniform distribution and preventing the undesired separation of components.

During the application or use of the liquid product, it is crucial to minimize unwanted phenomena such as dripping or sagging. These issues can adversely affect the product’s performance, aesthetics, and user experience. By incorporating good thixotropic properties, the liquid’s flow behavior can be modified to become more shear-thinning. This means that the viscosity decreases under the influence of applied forces, allowing for easier spreading or application. However, when the forces are removed, the viscosity quickly recovers, preventing excessive dripping or sagging.