Fumed Silica Performance | Rheological Control

What is Rheological Control?

Rheology mainly studies the flow properties and deformation behavior of substances under stress, strain, temperature, humidity, radiation and other conditions related to time factors. Rheological properties include viscosity, elasticity, plasticity and so on.

Rheology has a wide range of applications, such as plastic processing, coatings, food, cosmetics, medicine and other industries. Rheological control is closely related to the structure, construction characteristics and application performance of micro-materials.

Why rheological control is needed

Liquid system products, such as coatings, inks, adhesives, etc., need to have good thixotropy during production, storage, transportation and application, which means the product has a high viscosity in a static state when a certain external force is applied, it will become thinner, and when the external force is eliminated, the system will gradually return to its original state.

High-viscosity products can easily lead to processing difficulties. While low viscosity product will cause settlement and several layers during storage and transportation, as well as sagging and cratering issues.

Thixotropic agent, as an additive to adjust the viscosity and sagging of the system, has been widely used in many polymer materials such as coatings, paints, adhesives and so on. Common thixotropic thickening agents are fumed silica, organobentonite, castor oil, and polyamides.

How fumed silica helps in rheological control

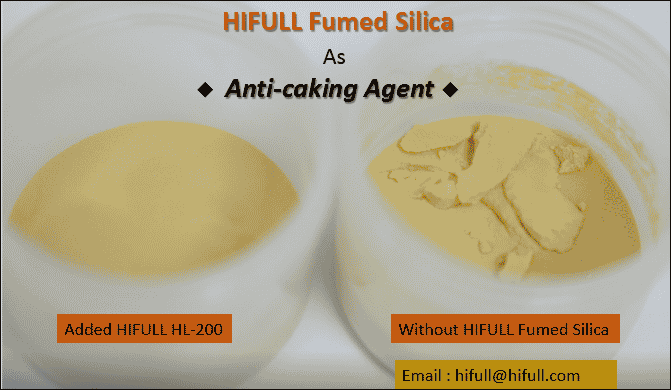

Fumed silica is a nano-material with amorphous structure, large specific surface area, nano-size particle size, high surface activity, high insulation, high thermal stability, chemical inertness, high purity, which can play a role in reinforcement, thickening, thixotropy, anti-caking, anti-sedimentation, anti-sagging and other functions. It is not only widely used in coatings, adhesives, potting materials, but also in the fields of bulletproof clothing, damping materials and so on.

HIFULL® Fumed Silica Manufacturer

Thixotropic Property

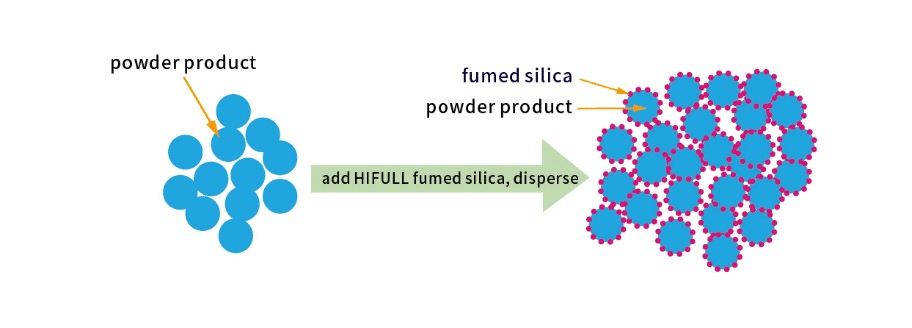

After been sheared and dispersed at a high speed, fumed silica is gradually dispersed into an aggregate form from an agglomerate form. The silanol groups on the surface of the fumed silica form hydrogen bonds, and the hydrogen bonds form a stable three-dimensional network structure in a product system so that the pigments and fillers can be firmly supported without layering and falling, performing excellent anti-settling effects.

When shearing force is applied, the network structure is destroyed, and viscosity decreases; and when the shearing force disappears, the network structure is restored, and viscosity increases, so that keeps uniform distribution and thickness, no fat edges.

Others Performance:

Application of fumed silica as rheological control agent

Hubei Huifu Nanomaterial Co., Ltd. produces many grades of HIFULL hydrophilic and hydrophobic fumed silica, which are widely used as rheological control additives in coatings, inks, adhesives, agriculture products and other industries.

Customers can choose the appropriate grade of fumed silica according to the polarity of fluid or resin, to fully play the function.

High polarity system: such as epoxy system. HIFULL HB-139 and HL-200 are recommended.

Non-polar systems: such as silicone systems. HIFULL HL-150, HL-200, HL-260, etc. are recommended.

Medium polarity system: such as polyurethane and acrylic acid system. HIFULL HB-139, HB-151, HB-152, HL-260 are recommended.

For products with high transparency requirements, hydrophilic fumed silica with large specific surface areas is recommended, such as HL-260/HL-300/HL-380/HL-450, etc.

Our technical service team can provide targeted product solutions for you, welcome to consult us. Email → tww@hifull.com .