Why Fumed Silica Need To Be Treated To Be Hydrophobic?

Fumed silica is available in both hydrophilic and hydrophobic forms. However, its hydrophilic nature makes it unsuitable for certain applications. Untreated fumed silica has many silanol groups on its surface, which absorb moisture and create a strong hydrogen bond network when added to a system. This bond network results in high viscosity and affects the stability of thickening and thixotropic properties. Polar solvents can easily break this bond network, causing instability in the system.

To overcome these issues, engineers treat fumed silica to convert its surface from hydrophilic to hydrophobic. Treating agents react with the surface silanol groups and form a layer of organic molecules, resulting in hydrophobic fumed silica. Hydrophobic fumed silica is beneficial in different product systems due to its good dispersing properties and ability to react with the product system through its silanol groups.

The Importance of Hydrophobicity in Fumed Silica

Hydrophobicity is a desirable property in fumed silica due to its many advantages in different applications. When treated to be hydrophobic, Its excellent dispersing properties, improved rheological properties, and moisture resistance make it a valuable material in various industrial and commercial applications.

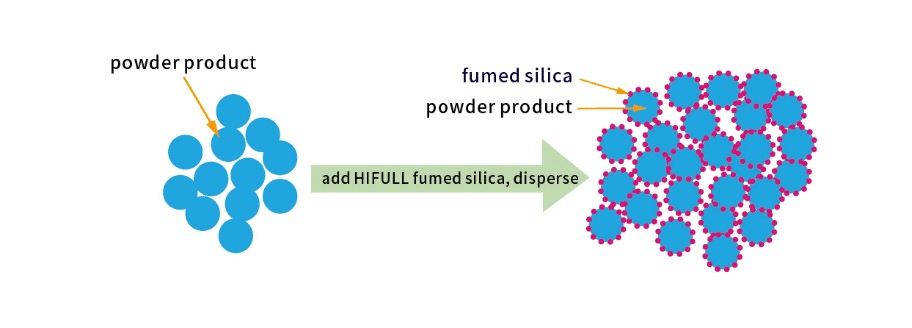

Hydrophobic fumed silica has excellent dispersing properties, which enable it to form stable suspensions in water-based systems. It repels water, which reduces the tendency of the silica particles to clump together, resulting in a more uniform dispersion. This makes hydrophobic fumed silica useful in applications where uniformity of the suspension is important, such as in coatings and inks.

Hydrophobic fumed silica has improved rheological properties compared to hydrophilic fumed silica. The water-repellent nature of hydrophobic fumed silica makes it useful as a thickening and gelling agent in water-based systems, resulting in stable and consistent viscosity. This makes hydrophobic fumed silica ideal for use in adhesives, sealants, and other applications where controlled viscosity is critical.

Hydrophobic fumed silica has improved moisture resistance compared to hydrophilic fumed silica. The water-repellent nature of hydrophobic fumed silica makes it ideal for use in applications where moisture resistance is essential, such as in electronic coatings and sealants.

| System | Function | Recommend Dosage | Hydrophobic Fumed Silica Suggest | Hydrophilic Fumed Silica Suggest |

|---|---|---|---|---|

| Polyurethane Sealants | sag-resistance, thixotropic, extrusion efficiency, stability( moisture control) | 3%-7% | HB-139 HB-151 | HL-200 |

| Acrylic Sealants | sag-resistance, settling-resistance, rheology control, thixotropic, extrusion efficiency | 3%-7% | HB-151 | HL-200 |

| Organic silicone | sag-resistance, reinforcement, rheology control, thixotropic, extrusion efficiency, stability( moisture control) | 5%-15% | HB-132 HB-630 HB-620 HB-612 HB-615 | HL-150 HL-200 |

| MS/SMP/SPU sealants | reinforce,extrusion efficiency,stability( moisture control) | 5%-10% | HB-139 HB-151 | / |

| butyl rubber-based sealants | sag-resistance, reinforce | 3%-7% | HB-151 | HL-200 |

| Polysulfide sealant | Reinforce, rheology control, thixotropic, | 3%-7% | HB-151 HB-139 | HL-200 |

Improved Flow Properties: Hydrophobic fumed silica has excellent flow properties, making it useful in the manufacture of high-quality coatings, such as automotive paints.

Cost-Effective: Hydrophobic fumed silica is cost-effective and can be used in small quantities to achieve desired properties. This makes it a popular choice in various industries, such as coatings, adhesives, and sealants.

Applications of Hydrophobic Fumed Silica

Hydrophobic fumed silica is a versatile material that finds its application in various industries due to its unique properties. It is a water-repellent material that has excellent dispersing properties, improved rheological properties, and moisture resistance.

As a result, it is widely used in applications such as inks, paints, adhesives, and sealants, cosmetics, pharmaceuticals, food and beverages, plastics and composites, energy, and rubber.

- Inks: Hydrophobic fumed silica is used as a pigment stabilizer in ink formulations. It helps to prevent settling and improves the flow properties of the ink.

- Paints and coatings: Hydrophobic fumed silica is used as a thickening and gelling agent in paint and coating formulations. It improves the viscosity, stability, and flow properties of the paint, resulting in high-quality coatings.

- Adhesives and sealants: Hydrophobic fumed silica is used as a thickening agent in adhesive and sealant formulations. It provides high shear strength and excellent thixotropic properties, making it ideal for use in construction and automotive applications.

- Cosmetics: Hydrophobic fumed silica is used in cosmetic formulations as a texture enhancer, a matting agent, and a viscosity control agent. It helps to improve the flow properties, stability, and texture of the cosmetic product.

- Pharmaceuticals: Hydrophobic fumed silica is used as a flow aid and a disintegrant in pharmaceutical formulations. It improves the flow properties of the powder and helps to facilitate the dissolution of the active ingredient.

- Food and Beverages: Hydrophobic fumed silica is used as an anti-caking agent and a carrier for flavors, vitamins, and other additives in food and beverage formulations.

- Plastics and Composites: Hydrophobic fumed silica is used as a reinforcing filler in plastics and composites. It improves the mechanical properties, such as stiffness and toughness, of the material.

- Energy: Hydrophobic fumed silica is used as a thickening agent and a rheology modifier in battery electrolytes and thermal insulation materials. It improves the performance and stability of these materials.

- Personal Care: Hydrophobic fumed silica is used in personal care formulations as a matting agent, an anti-aging agent, and a sunscreen agent. It helps to improve the texture and appearance of the product.

- Rubber: Hydrophobic fumed silica is used as a reinforcing filler in rubber formulations. It improves the mechanical properties, such as tear strength and abrasion resistance, of the rubber material.

The specific surface area of hydrophobic fumed silica can have an impact on its properties and performance in different applications. Generally, the larger the specific surface area of hydrophobic fumed silica, the better its ability to interact with the surrounding media and improve its properties.

Read More: How to Calculate Specific Surface Area of Fumed Silica

Here are some commonly used specifications and related parameters for hydrophobic fumed silica.

| HIFULL Hydrophobic fumed silica | Treating Agent | Specific surface area(BET) | pH value in 4% dispersion | Loss on drying*2 hours at 105℃ | Loss on ignition*2 hours at 1000℃ | Sio2 content* Based on ignited material | Tamped density-based on dried material | Carbon content based on dried material |

| Unit | m2/g | % | % | % | g/dm³ | % | ||

| HB-612 | HMDS | 140±20 | 5.5~7.5 | ≤0.7 | ≤2.0 | ≥99.8 | 40~60 | 0.7~1.3 |

| HB-615 | HMDS | 160±30 | 5.5~7.5 | ≤0.5 | ≤4.0 | ≥99.8 | 40~60 | 1.0~1.7 |

| HB-620 | HMDS | 210±30 | 5.5~8.0 | ≤0.5 | ≤4.0 | ≥99.8 | 40~60 | 1.5~2.5 |

| HB-630 | HMDS | 320±30 | 5.5~8.0 | ≤0.5 | ≤4.0 | ≥99.8 | 40~60 | 2.5~4.0 |

| HB-132 | HMDS | 120±40 | 7.0~8.5 | ≤0.5 | ≤4.0 | ≥99.8 | 40~60 | 2.5~4.0 |

| HB-135 | HMDS | 300±30 | 7.0~8.5 | ≤0.5 | ≤8.0 | ≥99.8 | 40~60 | 3.5~6.5 |

| HB-139 | PDMS | 100±20 | 5.5~7.5 | ≤1.5 | ≤10 | ≥99.8 | 40~60 | 4.5~6.5 |

| HB-151 | DDS | 130±20 | 3.7~4.5 | ≤0.7 | ≤2.5 | ≥99.8 | 40~60 | 0.6~1.2 |

| HB-152 | DDS | 160±20 | 3.7~4.5 | ≤0.7 | ≤2.5 | ≥99.8 | 40~60 | 0.8~1.6 |

| HB-151D | DDS | 130±20 | >4.0 | ≤0.7 | ≤2.5 | ≥99.8 | 40~60 | 0.6-1.2 |

| HB-152D | DDS | 170±20 | >4.0 | ≤0.7 | ≤2.5 | ≥99.8 | 40~60 | 0.8~1.6 |

HIFULL manufactures more than 10 grades of hydrophilic and hydrophobic fumed silica for your special choice. For product TDS, MSDS or sample-testing, price quotation, please check Datasheet or leave message to us.