Printing Ink

Fumed Silica in Printing Inks

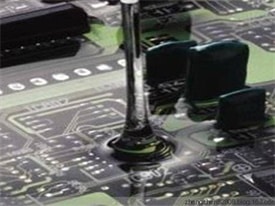

Fumed silica plays a broad role in the field of printing inks. Given that printing is a high-speed process, the rheological properties of the ink must be capable of withstanding various physical forces to achieve impeccable printing results. The ink should not splatter, needs to dry quickly, and must leave clear images on paper, polymer materials, or metal surfaces.

HIFULL’s Fumed Silica can impart superior properties to printing inks

Advantages of HIFULL Fumed Silica in the Printing Ink Industry

- Flexographic Printing: Flexographic printing essentially involves photosensitive resin and highly fluid ink. HIFULL’s Fumed Silica, as a raw material and an additive, enhances the performance, stability, and operability of systems and formulations used in the production and processing stages of flexographic printing.

- Inkjet Printing: The hydrophilic and hydrophobic product series from HIFULL can improve the printing process and print results. It helps control the flow of printer ink and manage ink fluidity for clearer printing outcomes.

- Screen Printing: Both hydrophilic and hydrophobic variants of HIFULL’s Fumed Silica are ideal choices for rheology control, minimizing issues of uneven printing and splattering.

- Offset Printing: Hydrophobic HIFULL’s Fumed Silica can lower the ink’s water absorption, eliminate foam, and improve the ink’s depth without affecting its surface gloss.

- Gravure Printing: HIFULL’s Fumed Silica can adjust viscosity and prevent pigment settling. In industrial ink, Fumed Silica can control the product’s fluidity.

This table outlines the diverse applications and benefits of using HIFULL’s hydrophilic and hydrophobic types of Fumed Silica in different printing methods, along with the recommended addition levels.

| Application Area | Function and Role | Recommended Addition | Recommended Hydrophilic Type | Recommended Hydrophobic Type |

|---|---|---|---|---|

| Flexographic Printing | Thicken and rheology control; Anti-settling/Suspension Aid | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

| Inkjet Printing | Thicken and rheology control; Anti-settling/Suspension Aid | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

| Screen Printing | Thicken and rheology control; Anti-settling/Suspension Aid | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

| Offset Printing | Thicken and rheology control; Anti-settling/Suspension Aid; Flow Aid; Color Enhancement; Clarity Improvement | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

| Gravure Printing | Thickening; Anti-settling/Suspension Aid | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

| Laser Printing | Dispersion Aid; Flow Control | 0.5-1.3% | HL-200 | HB-151, HB-615, HB-620 |

ABOUT HIFULL

Our main products are fumed silica SiO2, fumed titanium dioxide TiO2, and fumed alumina Al2O3. We get 20+ years of expertise and 20,000 tons of annual capacity. We supply total of 23 grades of hydrophilic & hydrophobic fumed silica. We get registration of REACH and pre-registration of K-REACH & KKDIK. We are the leading setting body of ISO18473-1:2015, ISO18473-3:2018, and ISO 23157:2021. Learn More About Hifull