Hubei Huifu Nanomaterial Co., Ltd’s Participation in “The Largest Gathering for the Coatings Community in Egypt”

We are delighted to announce that Hubei Huifu Nanomaterial Co., Ltd will be participating in “The Largest Gathering for the Coatings Community(MECS) in Egypt,” which will be held from June 19th to June 21st, 2023, at the Egypt International Exhibition Center (EIEC) in Cairo.

As a leading provider of innovative coating solutions, Hubei Huifu Nanomaterial Co., Ltd recognizes the significance of this prominent event in bringing together industry professionals, experts, and enthusiasts from the coatings community. It provides an exceptional platform for knowledge sharing, networking, and showcasing the latest advancements in the coatings industry.

About Middle East Coatings Show Egypt

Middle East Coatings Show(MECS) Egypt is the premier event in Cairo, connecting Egypt’s coatings industry. With 13 successful editions, it offers business and networking opportunities for manufacturers, suppliers, distributors, buyers, and technical specialists. The event facilitates face-to-face meetings, business transactions, and provides valuable insights into the latest processes. It’s a platform to exchange ideas, build a strong network, and stay updated in the industry.

During the Middle East Coatings Show 2023 EGYPT(19th June – 21st June), visitors are cordially invited to visit our booth, 1L81, located in Hall 1 of the Egypt International Exhibition Center (EIEC).

Our dedicated team of experts will be available to engage with attendees, discuss our comprehensive range of cutting-edge coating products, and provide insights into the latest technological innovations. We look forward to engaging with industry professionals, exploring potential partnerships, and gaining valuable insights into market trends and customer needs.

THE PROFESSIONAL coating solutions IN CHINA

Hubei Huifu Nanomaterial Co., Ltd. is a chemical manufacturer of nanomaterials in China, Our main products are fumed silica, fumed titanium dioxide, and fumed alumina Al2O3. We get 20+ years of expertise and 20,000 tons(and another 20,000 tons is in construction). we pride ourselves on delivering high-quality and sustainable coating solutions that meet the diverse needs of various sectors. Our product portfolio encompasses a wide range of applications, including automotive, aerospace, construction, and industrial coatings. We are committed to providing tailored solutions that enhance performance, durability, and environmental responsibility.、

| Types of Paints/ Coating | Functions of Fumed Silica |

| Protective Coatings | Improve adhesion and corrosion resistance |

| Inorganic Coating | Improve fire resistance, increase scrub resistance and coating film strength |

| Flame retardant Paint | Improve strength, abrasion resistance, flame retardancy and weather resistance of the topcoat paint, increase service life |

| Anti-radiation Coating | Enhance the electromagnetic wave absorption function of the coating |

| Superhydrophobic finishing Paint | Effectively improve the super hydrophobic ability and hardness of the coating film |

| Ceramic Coatings | Improve abrasion resistance, adhesion and hydrophobicity |

| Epoxy phenolic anticorrosive Paints | Improve mechanical properties & heat conduction, and extend the service life |

| Thermal barrier Coating | Good heat preservation and pore-forming effect |

| Quick-drying wall Paint | Improve drying speed, anti-sagging, coating film hardness, scratch resistance and good weather resistance |

| Powder Coatings | Avoid caking issues, improve flowing ability & storage stability |

| Multi-color Paint | Improve the hydrophobicity, scrub resistance and weather resistance |

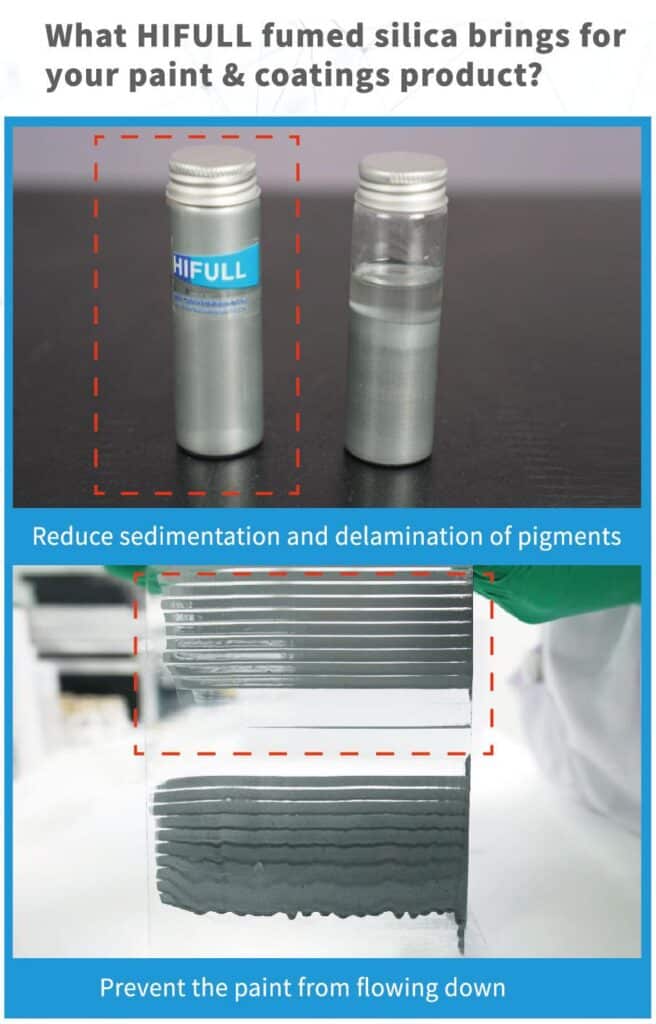

manufacturing and storage process

- Dispersion of pigment and filler

- Stability of pigment and filler

- Avoid sedimentation

- Flow aid for powder coatings

- Anti-caking for powder coatings

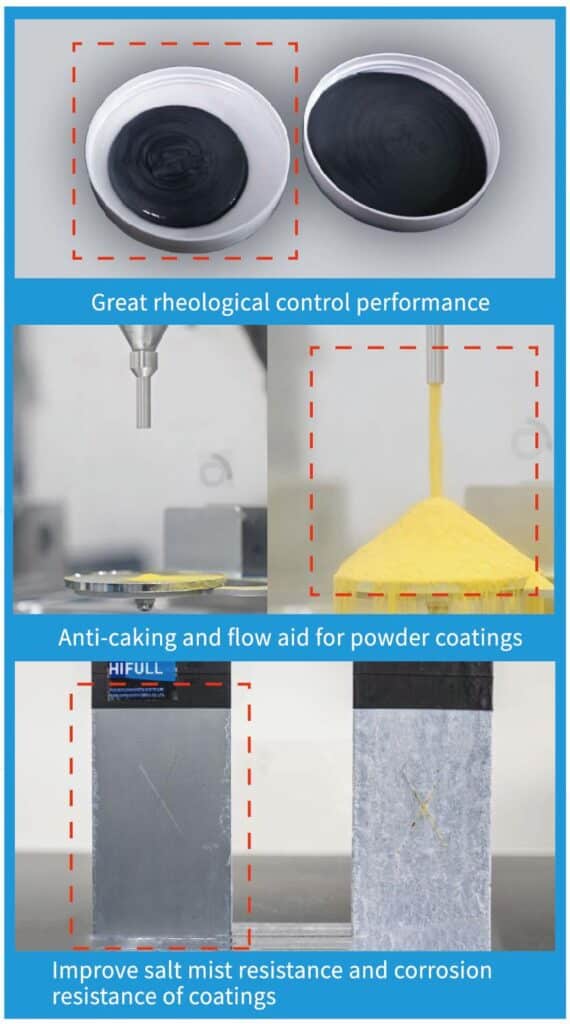

process of applying coatings

- Excellent thixotropic properties

- Anti-sagging

- Function of orientation for metal powder

- Improve powder coating coverage

drying process of coatings

- Improve hydrophobic properties

- Improve anti-aging and anti-corrosive properties

- Enhance density and adhesion of paint or coatings

- Improve abrasion resistance and scratch resistance

- Keep color intensity

- Matting properties

Tips: The red boxed area indicates the addition of HIFULL Fumed Silica

Would you like to learn more information? You can consult with us online, visit our booth at the exhibition, or download our technical documents.

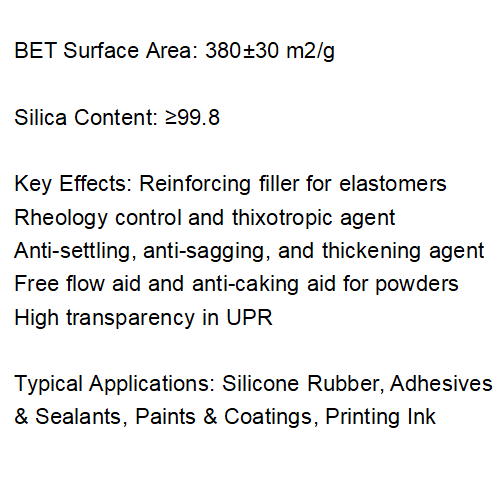

Fumed Silica Grade Recommendation for Paint & Coatings

HIFULL Certificate

Certificates & Awards

56 core patent technologies

PCT Patent

Invention & Utility Model Patent

HIFULL Gallery

Attend Middle East Coatings Show in Mar 2018

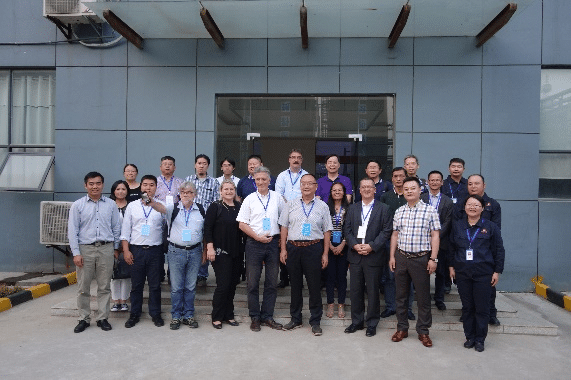

Attend Middle East Coatings Show in Mar 2018 Dr Martin, Chairman of ISO/TC 256, took the team and visited Huibei Huifu in Sep 2016

Dr Martin, Chairman of ISO/TC 256, took the team and visited Huibei Huifu in Sep 2016 Employee attended the party to celebrate the Mid-autumn Festival in Sep 2022

Employee attended the party to celebrate the Mid-autumn Festival in Sep 2022 Russia clients visited our factory for cooperation in Mar 2023

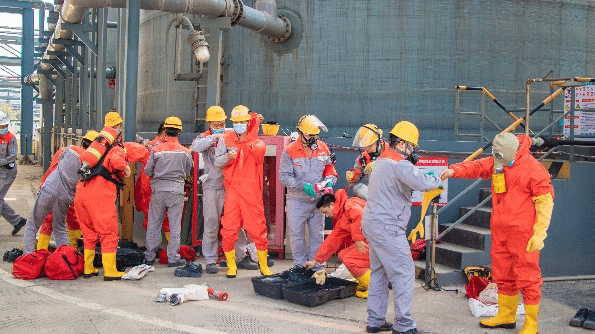

Russia clients visited our factory for cooperation in Mar 2023 Fire drill in Huifu factory in June 2022

Fire drill in Huifu factory in June 2022